What is Plastic Injection Molding? Understanding the Process, Advantages, and Applications

Plastic injection molding is a widely used manufacturing process in which molten plastic is injected into a mold cavity to create a wide range of products with high accuracy and precision. From toys to automotive parts, plastic injection molding has become an essential part of our daily lives. In this article, we will dive deeper into the plastic injection molding process, its advantages, and the applications in various industries.

Table of Contents

- Introduction

- History of Plastic Injection Molding

- The Plastic Injection Molding Process

- Clamping

- Injection

- Cooling

- Ejection

- Advantages of Plastic Injection Molding

- High Efficiency and Production Rates

- Cost-Effective

- Accurate and Precise

- Versatile

- Applications of Plastic Injection Molding

- Automotive

- Medical

- Aerospace

- Consumer Goods

- Packaging

- Construction

- Challenges of Plastic Injection Molding

- Design and Tooling

- Material Selection

- Quality Control

- Conclusion

- FAQs

1. Introduction

Plastic injection molding is a manufacturing process that involves melting plastic pellets and injecting them into a mold cavity to create a product. This process has become a popular method of mass production due to its efficiency, accuracy, and versatility. With advances in technology, plastic injection molding has become an essential part of many industries, including automotive, medical, aerospace, consumer goods, packaging, and construction.

2. History of Plastic Injection Molding

The history of plastic injection molding dates back to the late 19th century when John Wesley Hyatt invented celluloid, the first synthetic plastic material. However, it was not until the 1930s when James Watson Hendry developed the first screw injection machine, which revolutionized the plastic injection molding process. Since then, the plastic injection molding industry has continued to grow, with new materials and techniques being developed to improve the process.

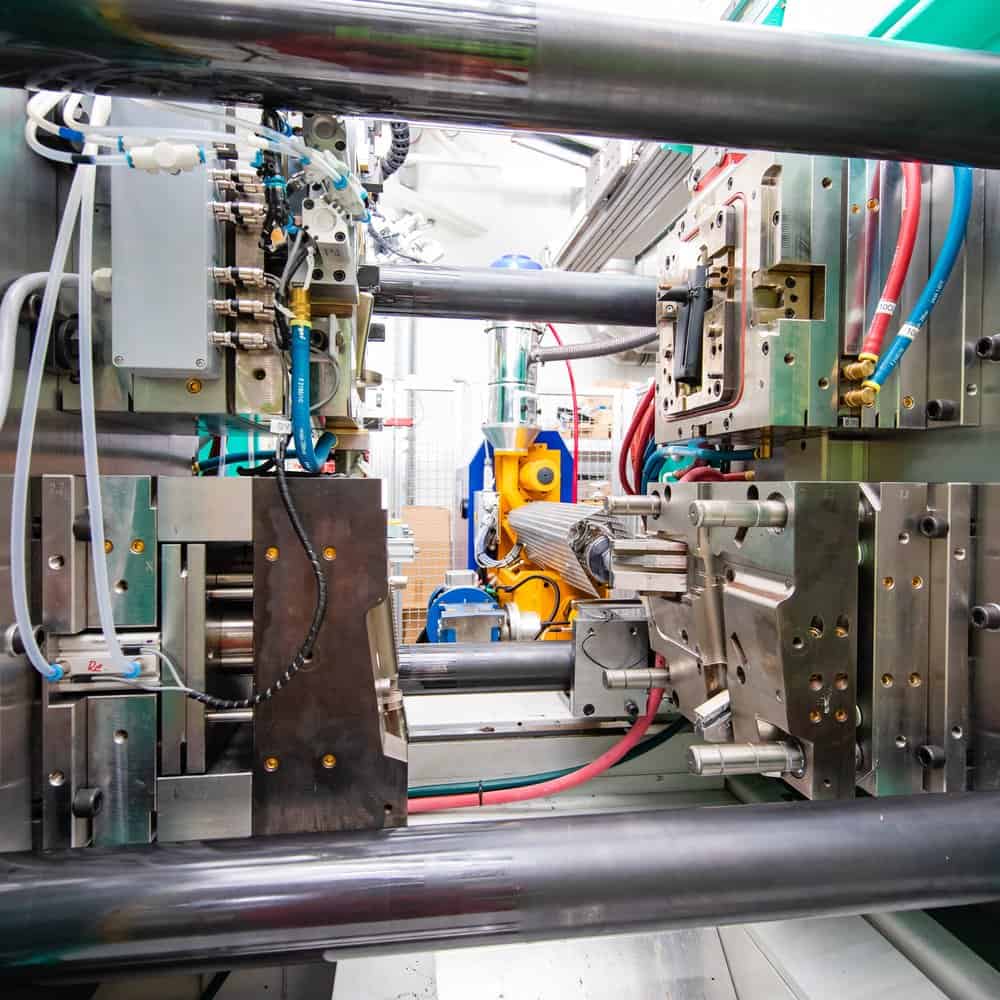

3. The Plastic Injection Molding Process

The plastic injection molding process involves four main stages: clamping, injection, cooling, and ejection.

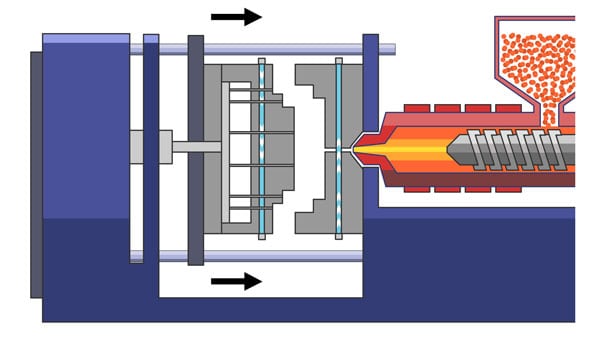

Clamping (Step 1)

The first stage is clamping, where the two halves of the mold are closed together with enough force to withstand the pressure of the injected plastic. The amount of force required depends on the size and complexity of the product.

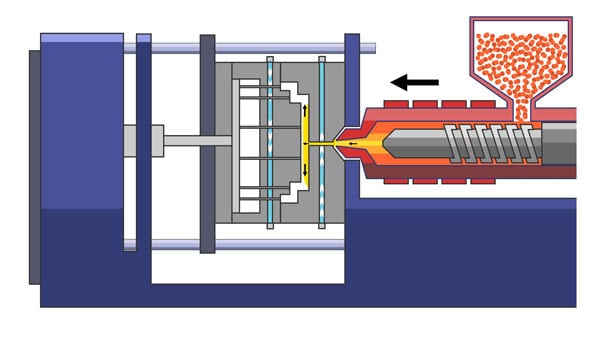

Injection (Step 2)

Once the mold is clamped, the second stage begins, which is injection. In this stage, molten plastic is injected into the mold cavity through a nozzle at high pressure and speed. The plastic then fills the cavity and takes the shape of the mold.

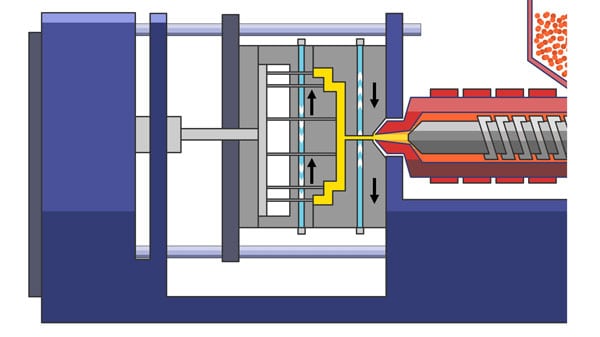

Cooling (Step 3)

After the plastic is injected, the third stage is cooling. The mold is cooled down to allow the plastic to solidify and take its final shape. The cooling time depends on the size and thickness of the product.

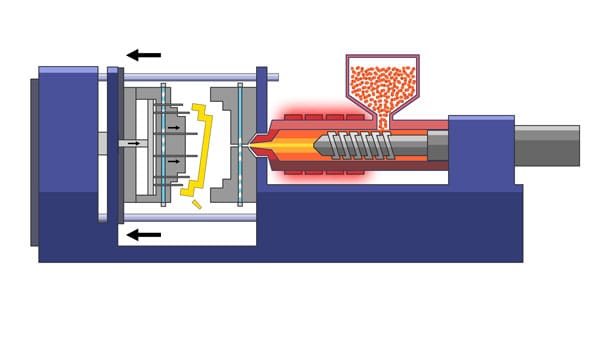

Ejection (Step 4)

Once the plastic has solidified, the final stage is ejection. The mold is opened, and the product is ejected from the mold cavity by a ejector pin. The product is then inspected and trimmed to remove any excess plastic.

4. Advantages of Plastic Injection Molding

Plastic injection molding offers several advantages compared to other manufacturing processes, including:

High Efficiency and Production Rates

Plastic injection molding is a highly efficient process that can produce large volumes of products quickly and consistently. The use of automation and robotics in the process has also improved efficiency and reduced labor costs.

Cost-Effective

Plastic injection molding can be a cost-effective method of production, especially for large volume runs. The initial tooling costs can be high, but the cost applied over the lifespan of the mold, such as maintenance and repairs, are significantly lower compared to other manufacturing processes.

Accurate and Precise

Plastic injection molding offers high accuracy and precision in the production of products. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) has improved the level of precision in the design and production process.

Versatile

Plastic injection molding can be used to create a wide range of products with varying shapes, sizes, and complexities. The process allows for the use of different types of plastics and additives, which can be customized to meet specific requirements.

Consistency

The automated nature of plastic injection molding means that each part produced will be identical to the others, ensuring consistency and reliability in the final product.

Design Flexibility

Injection molding offers design flexibility, allowing for complex and intricate part geometries to be created with ease. In addition, parts can be designed with features such as undercuts and threads, which can be difficult or impossible to produce using other manufacturing methods.

5. Applications of Plastic Injection Molding

Plastic injection molding has a wide range of applications in various industries, including:

Automotive

The automotive industry is one of the largest users of plastic injection molding, with products ranging from interior components to engine parts.

Medical

The medical industry uses plastic injection molding to produce products such as syringes, medical implants, and laboratory equipment.

Aerospace

The aerospace industry uses plastic injection molding to produce components for airplanes and spacecraft, such as cockpit components and interior parts.

Consumer Goods

Plastic injection molding is used in the production of consumer goods such as toys, kitchenware, and electronics.

Packaging

The packaging industry uses plastic injection molding to produce various types of packaging, including bottles, containers, and lids.

Construction

The construction industry uses plastic injection molding to produce products such as PVC pipes, fittings, and roofing tiles.

6. Challenges of Plastic Injection Molding

Despite the many advantages of plastic injection molding, there are also some challenges that come with the process. These challenges include:

Design and Tooling

Designing the mold and the product to be produced requires careful consideration to ensure that the final product meets the desired specifications. The tooling process can also be time-consuming and expensive.

Material Selection

Selecting the right material for the product is crucial to ensure that it meets the required performance and durability standards. The selection of the wrong material can lead to product failure or defects.

Quality Control

Ensuring that the final product meets the required quality standards can be challenging. Quality control measures need to be put in place to detect and correct any defects or inconsistencies in the production process.

7. Summary

Plastic injection molding is a versatile, efficient, and cost-effective manufacturing process that has become an essential part of many industries. The process offers high accuracy and precision, allowing for the production of products with varying shapes, sizes, and complexities. Despite the challenges that come with the process, plastic injection molding continues to evolve, with new materials and techniques being developed to improve the process and meet the demands of various industries.

8. FAQs

- What types of plastics can be used in plastic injection molding?

- How long does the plastic injection molding process take?

- What are the advantages of using plastic injection molding in the automotive industry?

- How can quality control be implemented in the plastic injection molding process?

- What are the most common applications of plastic injection molding?

If you want to further dig into in depth knowledge in injection molding, blow links will help to give you all of the related info.

Https://plasticsindustry.org

Https://en.wikipedia.org/wiki/Injection_moulding

Looking for one-stop mechanical solution starting from scratch the 3D reviewing, prototyping, low volume manufacturing, tooling & plastic injection molding? Visit our homepage: https://vacuumcastingsz.com.

Magnificent beat I would like to apprentice while you amend your site how can i subscribe for a blog web site The account helped me a acceptable deal I had been a little bit acquainted of this your broadcast offered bright clear idea

Nutra Gears I just like the helpful information you provide in your articles

Mangaclash Hi there to all, for the reason that I am genuinely keen of reading this website’s post to be updated on a regular basis. It carries pleasant stuff.

Smartcric I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

BWER is Iraq’s premier provider of industrial weighbridges, offering robust solutions to enhance efficiency, reduce downtime, and meet the evolving demands of modern industries.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

As Iraq’s leading business information portal, BusinessIraq.com provides in-depth coverage of crucial sectors including oil and gas, construction, banking, and telecommunications. Our dedicated team of journalists and analysts delivers exclusive reports on major infrastructure projects, investment opportunities, and regulatory changes affecting both local and international businesses. From Baghdad’s emerging startups to Kurdistan’s established enterprises, we track the stories that matter to decision-makers.

The platform not only delivers breaking news but also features in-depth analyses and opinion pieces, ensuring that readers are well-informed. Check out the latest articles on economic policies and market developments at Iraq Business News.

onion dark website darknet sites

With the Iraqi government implementing various reforms to stimulate growth, having access to reliable news sources is critical. Iraq Business News covers government initiatives and regulatory changes that affect the business landscape, empowering companies to adapt and thrive.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/es/register?ref=T7KCZASX

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Your article helped me a lot, is there any more related content? Thanks!

I am really inspired together with your writing abilities

and also with the structure for your blog.

Is that this a paid theme or did you modify it yourself?

Either way keep up the nice high quality writing, it is

uncommon to look a nice weblog like this one nowadays.

Beacons AI!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Unlock exciting rewards with the latest 1xBet promo code! Whether you’re from Bangladesh, Pakistan, India, Nepal, Sri Lanka, Egypt, or the Philippines, you can claim amazing bonuses like free bets, free spins, and welcome bonuses with our updated 1xBet promo codes today. Use your 1xBet promo code for registration to start betting without a deposit or boost your first deposit with extra cash. Enjoy special offers with the 1xBet official promo code, perfect for app users and desktop players. Get your 1xBet free promo code today and experience top-tier betting promotions before they expire! No matter where you are, finding the right 1xBet promo code today means unlocking bigger chances to win, with offers perfectly tailored for players across Bangladesh, Pakistan, India, Nepal, Sri Lanka, Nigeria, Egypt, and the Philippines.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Your article helped me a lot, is there any more related content? Thanks!

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?